Most dry natural ingredients needs to be pasteurized or sterilized for safety. Several solutions exist like irradiation, ETO, ozone and UV. However, steam sterilization is the only efficient and globally recognized solution.

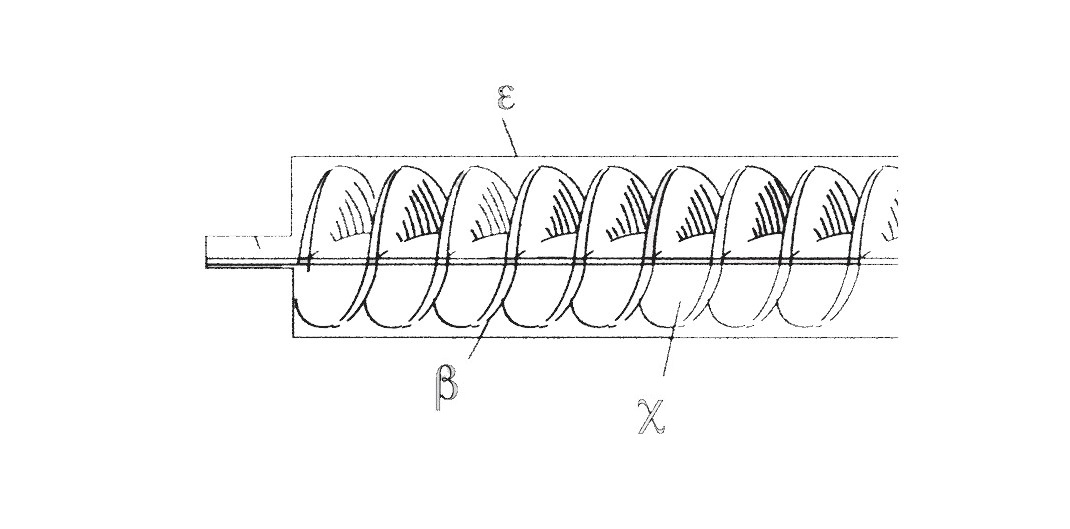

SAFESTERIL® uses an innovative continuous system sterilization process, which is completely safe and natural. It only uses heat to safely and gently reduce the microbial load of sensitive raw materials, without impacting important characteristics like flavor, taste, color or moisture.

SAFESTERIL® will make your product safer for the consumer, while maintening its high quality.

Safesterilization of spices or dried materials is the ultimate solution for micro-reduction.

Thanks to an homogenuous treatment due to a non static exposure to steam and to the non condensation of steam on the product, SAFESTERIL® has a minimal impact on the color and other heat sensitive properties.

Since the product is continuously mixed, steam penetrates in the heart of product without condensin, so that even sticky powders can be treated without agglomerating. Outlet product can be directly packed without any mashing step, as its granulometry does not change.