Worldwide patents / Brevets internationaux

Years of experience / Années d'expérience

Units installed worlwide / Unités installées

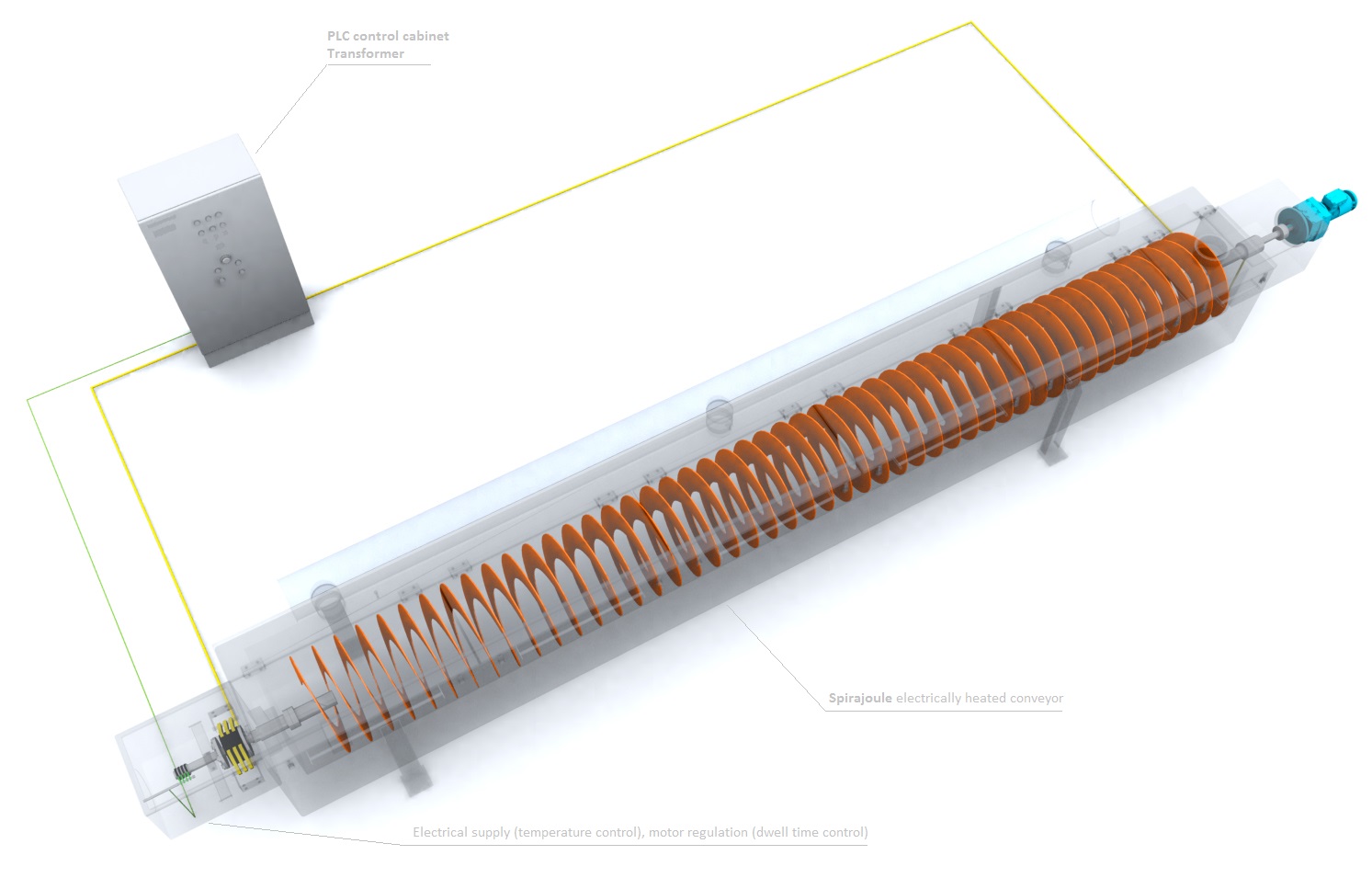

The Spirajoule technology is an exclusive and patented process for thermal treatment. It is designed with a worn screw conveyor electrically heated by a low voltage current. The technology is a simple and economical process with the accurate and efficient operation offering the heat treatment up to 250°C for a variety of bulk products and applications.

- Simple = Easy to operate

- Robust = Very low maintenance

- No electrical heater = No sensible element

- No double jacket = No hot fluid or gas needed

- Plug flow reactor = FIFO reactor

Process are multiple with a single machine:

- Heating

- Low temperature drying

- Pasteurization

- Steam sterilization

- Toasting and roasting

La technologie Spirajoule est un procédé exclusif et breveté de traitement thermique. Il est basé sur l’utilisation d’une vis sans fin chauffé électriquement par un courant basse tension. La technologie est simple et économique à l’utilisation précise et efficace qui offre un traitement thermique jusqu’à 250°C pour une grande variété d’applications et tout type de produits en vrac.

- Simple = Facile d’utilisation

- Robuste = Peu de maintenance

- Pas d’éléments chauffants = Pas d’éléments sensibles

- Pas de double enveloppe = Aucun gaz ou fluide caloporteur requis

- Installation adaptable = Réacteur FIFO (“First In First Out”)

Les procédés sont multiples avec le même équipement:

- Chauffage

- Séchage basse température

- Pasteurisation

- Stérilisation à la vapeur

- Grillage et toastage

The Spirajoule® technology is an exclusive process for thermal treatment. It is designed with a patented worm screw conveyor electrically heated by a low voltage current. The screw heats the product due to the Joule effect. It can be heated up to 250°C with the PTFE sheet.

Spirajoule provides optimal thermal transfer to finely divided wet and dry products. Maximum efficiency is achieved by the product’s direct contact to the heated screw.

Product dwell time, temperature and air extraction are fully adjustable.

Full inspection of the internal chamber eases cleaning and product changeover.

The electrically heated coreless screw also allows injection of steam or dry air.

For all shapes, powders, seeds, leaves, cuts,…

Easy to use process, with low cost and low maintenance, the Spirajoule® is a continuous and homogeneous treatment which keeps the product non-denatured after treatment.

The Spirajoule® is delivered with a control panel to monitor the process and a rectifier sized by ETIA will supply the required power to the screw conveyor.

The SPIRAJOULE® process series is best for thermal treatments like sterilization (while preserving microbiological and organoleptic properties), roasting (of meat for example), toasting for seeds, drying, defrosting, conveying with temperature maintaining… for all kinds of inputs used in the chemical industry, food ingredients (for example: spices, herbs, cereals, dehydrated fruits or vegetables, seafood…), etc…

La technologie Spirajoule® est un procédé exclusif de traitement thermique. Il est conçu avec une vis sans fin chauffé électriquement par un courant basse tension. La vis chauffe le produit par effet Joule et son design incluant une plaque de Téflon permet un chauffage jusqu’à 250°C.

Le Spirajoule permet un transfert thermique optimal aux solides divisés secs. Une efficacité maximale est atteinte par contact direct de la matière avec la vis chauffante.

Le temps de séjour de la matière, la température et l’extraction d’air sont des paramètres ajustables.

Un accès intégral à l’intérieur de la chambre facilite les opérations de nettoyage et les changements de matières entrantes.

La vis sans fin chauffée électriquement permet l’injection de vapeur ou d’air chaud et sec.

Convient pour tout type de matières: poudres, graines, feuilles, coupes…

Procédé simple d’utilisation, avec des coûts d’opération et de maintenance réduits, le Spirajoule® est un traitement homogène et continu qui gardera le produit non-dénaturé après traitement.

Le Spirajoule® est livré avec une armoire de contrôle et un transformateur dimensionné par ETIA qui fournira la puissance de chauffe requise à la vis.

Le procédé SPIRAJOULE® est le meilleur pour des traitements thermiques comme la stérilisation (tout en préservant les propriétés organoleptiques et microbiologiques), grillage (de viande par exemple), toastage des graines, séchage, décongélation, convoyage en maintenant une température cible… pour tout type d’entrants du domaines de l’industrie chimique, alimentaire (par exemple: épices, herbes, céréales, fruits et légumes déshydratés,…), etc…